The pipeline tape coating suspected of being responsible for a rupture on the Enbridge WestCoast Energy line is also coating another 500 km of pipe that runs through BC.

On October 9th of last year, an Enbridge pipeline exploded about 13 kms outside of Prince George causing an evacuation of the Shelley Reserve and inciting an investigation by the Transportation Safety Board.

Jennifer Philopoulos, Senior Pipeline Investigator with the TSB, said in the analysis of the ruptured pipeline they found numerous indications of “stress corrosion cracking.”

“That particular crack exceeded what we call the critical crack size, resulting in a rupture of the pipeline,” she explained. “The analysis also found that the mode of cracking was consistent with ‘near-neutral pH stress corrosion cracking’.”

“There are specific issues associated with near-neutral pH stress corrosion cracking, in particular with the use of polyethylene tape coating on pipelines that were built in certain eras. The issue is that we understand that pipelines with this type of coating are particularly susceptible to near neutral pH corrosion cracking.”

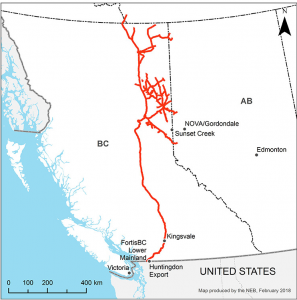

According to Philopoulos, approximately 500 km of the Westcoast’s (Enbridge) Transmission South system, which stretches from south of Chetwynd, BC to the southernmost point at the Canada/U.S. border at Huntingdon, still has the polyethylene tape coating.

She said that in the regulatory framework, pipeline companies are required to have stress corrosion management plans that identify risks associated with their pipeline, but she could not comment further on how Enbridge had been doing that prior to the explosion in October.

“I can’t go into all those details yet because we are getting into some of the analysis for my current investigation. But right now what we are trying to do is bring awareness to the importance of ensuring that those management plans address pipelines with that coating and address them in a way that allows them to prevent something like this happening again.”

Despite a request from MyPGNow, Enbridge would not provide the areas of the pipeline that still have the coating, however, media spokesperson Jesse Semko, said that the tape was commonly used in the 1960s and ’70s, has a good track record, and that the company is working on improving its management system.

“Since the Shelley incident, we have made improvements to this integrity program, undertaking a comprehensive assessment of the entire T-South system with a particular emphasis on stress corrosion cracking and implementing improved screening criteria to evaluate and schedule maintenance work,” said Semko.

“This involves a more conservative approach to identify areas that may require maintenance or inspection earlier. Going forward we will be increasing the frequency of inline pipeline inspections by 30 percent that looks for stress corrosion cracking.”

The National Energy Board also said improvements have been made since the pipeline rupture.

“Since the incident occurred, the NEB has conducted 9 field inspections and met with the company to review their return to the service plan and discuss integrity management, inspection tool reliability, and the structure/timing of Engineering Assessments (EA) required,” said spokesperson Chantal Macleod.

“As part of their EA’s that demonstrate the pipe is fit for service, Westcoast has conducted in-line inspections using the most current technology to identify any stress corrosion cracking (SCC) and they have conducted numerous excavations to evaluate and mitigate any SCC indications.”

The final report from the TSB is in the writing process, but Philopoulos said it may still be “many months” before it is released.